Structural featrures: Structural featrures:

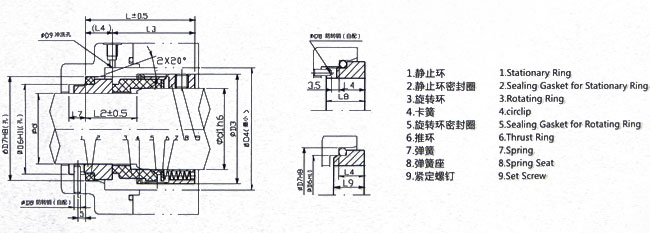

It adopts a wedge ring made of PTFE, PTFE filling or flexible graphite as the auxiliary gasket ring to improve the sealí»s working temperature and abrasion resistance. With a small spring structure and an unbalanced seal, it has short axial dimensions and a uniform compression on the seal end face. With a wide universality, it conforms to ISO 3069 and DIN 2460.

Application scope: Application scope:

Pressure: í▄6MPa

Temperature: -50~250íŠ

Linear speed: í▄25m/s

Application: Ití»s used for sealing rotation axes of such equipment as industrial pumps, reactors and compressors in chemical engineering, petrochemical, oil refining, refrigeration, pharmacy, papermaking, water supply and drainage, sewage treatment and so on. Its applicable media include water, oil and other slightly corrosive liquids.

| Model |

d |

d1 |

D3 |

D4 |

D6 |

D7 |

D8 |

D9 |

L |

L2 |

L3 |

L4 |

L7 |

L8 |

L9 |

| DS59B-20 |

20 |

24 |

38 |

40 |

29 |

35 |

3 |

6.5 |

45 |

20 |

31.5 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-22 |

22 |

26 |

40 |

42 |

31 |

37 |

3 |

6.5 |

45 |

20 |

31.5 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-24 |

24 |

28 |

42 |

44 |

33 |

39 |

3 |

6.5 |

47.5 |

20 |

34.2 |

13.3 |

9 |

20.3 |

14.5 |

| DS59B-25 |

25 |

30 |

44 |

46 |

34 |

40 |

3 |

6.5 |

47.5 |

20 |

34.5 |

13 |

9 |

20 |

14 |

| DS59B-28 |

28 |

33 |

47 |

49 |

37 |

43 |

3 |

6.5 |

50 |

20 |

37.5 |

12.5 |

9 |

19.5 |

13.5 |

| DS59B-30 |

30 |

35 |

49 |

51 |

39 |

45 |

3 |

6.5 |

50 |

20 |

38 |

12 |

9 |

19 |

13 |

| DS59B-32 |

32 |

38 |

54 |

58 |

42 |

48 |

3 |

6.5 |

50 |

20 |

38 |

12 |

9 |

19 |

13 |

| DS59B-33 |

33 |

38 |

54 |

58 |

42 |

48 |

3 |

6.5 |

50 |

20 |

38 |

12 |

9 |

19 |

13 |

| DS59B-35 |

35 |

40 |

56 |

60 |

44 |

50 |

3 |

6.5 |

50 |

20 |

38 |

12 |

9 |

19 |

13 |

| DS59B-38 |

38 |

43 |

59 |

63 |

49 |

56 |

4 |

6.5 |

52.5 |

23 |

39.5 |

13 |

9 |

20 |

14 |

| DS59B-40 |

40 |

45 |

61 |

65 |

51 |

58 |

4 |

6.5 |

52.5 |

23 |

39.5 |

13 |

9 |

20 |

14 |

| DS59B-43 |

43 |

48 |

64 |

68 |

54 |

61 |

4 |

6.5 |

52.5 |

23 |

39.5 |

13 |

9 |

20 |

14 |

| DS59B-45 |

45 |

50 |

66 |

70 |

56 |

63 |

4 |

6.5 |

52.5 |

23 |

39.5 |

13 |

9 |

20 |

14 |

| DS59B-48 |

48 |

53 |

69 |

73 |

59 |

66 |

4 |

6.5 |

52.5 |

23 |

39.5 |

13 |

9 |

20 |

14 |

| DS59B-50 |

50 |

55 |

71 |

75 |

62 |

70 |

4 |

6.5 |

57.5 |

25 |

44 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-53 |

53 |

58 |

78 |

83 |

65 |

73 |

4 |

6.5 |

57.5 |

25 |

44 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-55 |

55 |

60 |

80 |

85 |

67 |

75 |

4 |

6.5 |

57.5 |

25 |

44 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-58 |

58 |

63 |

83 |

88 |

70 |

78 |

4 |

6.5 |

62.5 |

25 |

49 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-60 |

60 |

65 |

85 |

90 |

72 |

80 |

4 |

6.5 |

62.5 |

25 |

49 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-63 |

63 |

78 |

88 |

93 |

75 |

83 |

4 |

6.5 |

62.5 |

25 |

49 |

13.5 |

9 |

20.5 |

14.5 |

| DS59B-65 |

65 |

70 |

90 |

95 |

77 |

85 |

4 |

6.5 |

62.5 |

25 |

49 |

13.5 |

9 |

20.5 |

14.2 |

| DS59B-70 |

70 |

75 |

95 |

104 |

83 |

92 |

4 |

6.5 |

70 |

28 |

55.5 |

14.5 |

9 |

21.5 |

15.2 |

| DS59B-75 |

75 |

80 |

104 |

109 |

88 |

97 |

4 |

6.5 |

70 |

28 |

55.5 |

14.5 |

9 |

21.5 |

15.2 |

| DS59B-80 |

80 |

85 |

109 |

114 |

95 |

105 |

4 |

9.5 |

70 |

28 |

55 |

15 |

9 |

22 |

15.7 |

| DS59B-85 |

85 |

90 |

114 |

119 |

100 |

110 |

4 |

9.5 |

75 |

28 |

60 |

15 |

9 |

22 |

15.7 |

| DS59B-90 |

90 |

95 |

119 |

124 |

105 |

115 |

4 |

9.5 |

75 |

28 |

60 |

15 |

9 |

22 |

15.7 |

| DS59B-95 |

95 |

100 |

124 |

129 |

110 |

120 |

4 |

9.5 |

75 |

28 |

60 |

15 |

9 |

22 |

15.7 |

| DS59B-100 |

100 |

105 |

129 |

134 |

115 |

125 |

4 |

9.5 |

75 |

28 |

60 |

15 |

9 |

22 |

15.7 |

|